Holding about 15% (15 million tons) of the world’s gilsonite reserves, Iran has the third-largest reserve of this mineral. The natural bitumen deposits of Iran lie along the main Zagros fault with a NW–SE direction. These deposits are found in the folded Zagros belt, which is 200–250 km wide. Gilsonite reserves of Iran are generally located in the west of the country and Kermanshah province holds about 75% of gilsonite reserves.

Gilsonite has been used as an effective component and additive in a variety of applications, therefore the most important research and studies have focused on novel processing techniques to produce new and higher quality grades of this valuable mineral. Bahrami et al. released one of the most recent and well-known studies in 2021, which is as follows:

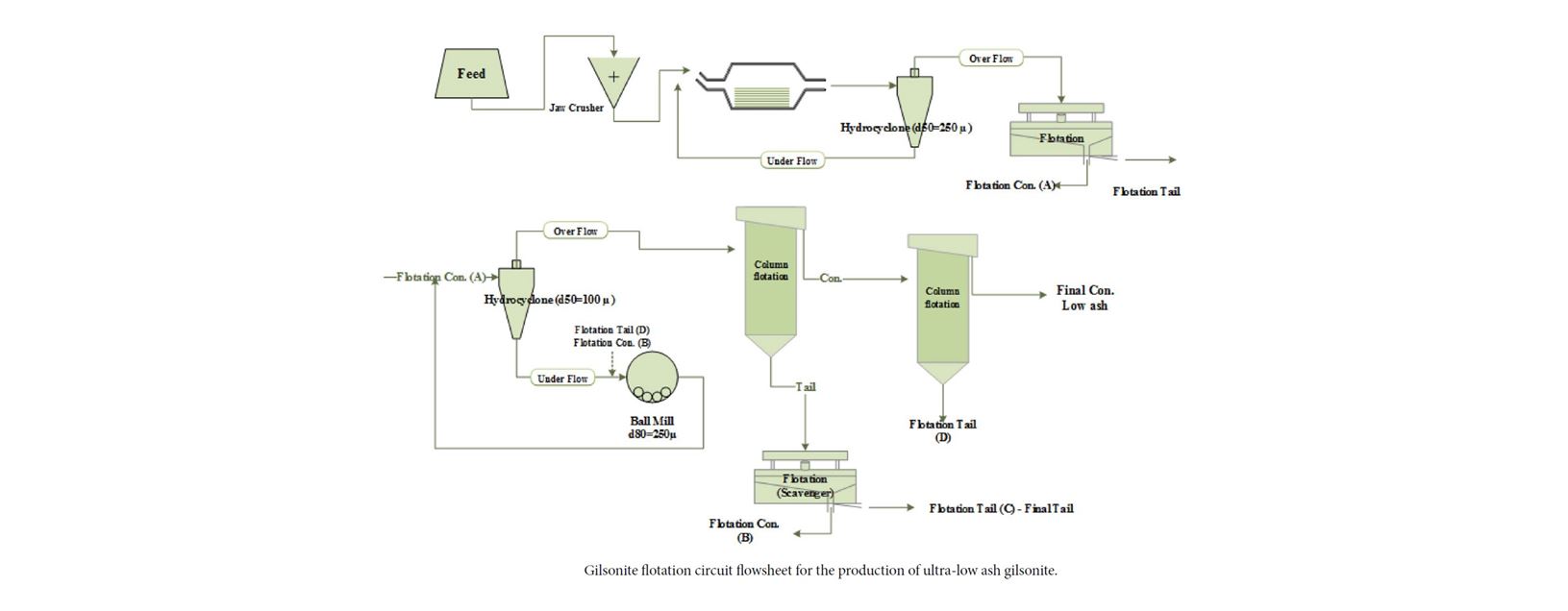

Gilsonite has a wide variety of applications in the industry, including the manufacture of electrodes,paints and resins, as well as the production of asphalt and roof-waterproofing material. Gilsonite ash is a determining parameter for its application in some industries (e.g., gilsonite with ash content < 5% used as an additive in drilling fluids, resins). Due to the shortage of high grade (low ash) gilsonite reserves, the aim of this study is to develop a processing flowsheet for the production of ultra-lowash gilsonite (< 5%), based on process mineralogy studies and processing tests. For this purpose, mineralogical studies and flotation tests have been performed on a sample of gilsonite with an average ash content of 15%. The samples studied in this research are collected from gilsonite mines located in the western part of Kermanshah province. According to mineralogical studies, carbonates and clay minerals are the main associated impurities (more than 90 vol.%). Furthermore, sulfur was observed in two forms of mineral (pyrite and marcasite) and organic in the structure of gilsonite. Most of these impurities are interlocked with gilsonite in size fractions smaller than 105 μm. The size fraction of +105−420 μm has a higher pure gilsonite (approximately 90%) than other size fractions. By specifying the gangue minerals with gilsonite and the manner and extent of their interlocking with gilsonite, +75−420 μm size fraction selected to perform flotation tests. Flotation tests were performed using different reagents including collector (Gas oil, Kerosene and Pine oil), frother (MIBC) and depressant (sodium silicate, tannic acid, sulfuric acid and sodium cyanide) in different dosages. Based on the results, the use of kerosene collector, MIBC frother and a mixture of sodium silicate, tannic acid, sulfuric acid and sodium cyanide depressant had the most favorable results in gilsonite flotation in the rougher stage. Cleaner and recleaner flotation stages for the rougher flotation concentrate resulted in a product with an ash content of 4.89%. Due to the interlocking of gilsonite with impurities in size fractions −105 μm,it is better to re-grinding the concentrate of the rougher stage beforehand flotation in the cleaner and recleaner stages. Finally, based on the results of mineralogical studies and processing tests, a processing flowsheet including crushing and initial granulation of gilsonite, flotation in rougher, cleaner and recleaner stages has been proposed to produce gilsonite concentrate with < 5% ash content and recovery of 86.75%.

To receive the full manuscripts of this paper, please refer to one of the following links:

To receive information about Simone Pars's Gilsonite product (SIMONO Gls), send an email to R&D@simonpars.com.